Implementing a new electronics system design is always a tradeoff between wants and needs;

risk vs. reward. To make sure the Marketing Requirements Document (MRD) is met or adhered

to as closely as possible being the primary directive.

Ideally, new support components for the solution would be updated to accommodate greater

efficiency, reliability, solution density, cost savings and reduce the possibility of supply

constraints.

Assessing new technologies quickly and in a sufficiently detailed manner is fundamental to the

decision-making process when designing solutions.

Until recently, evaluating regulators and assessing their capability has been an arduous task.

Limited time and bench resources meant that engineers did not get the opportunity to assess all

their options.

Equally frustrating to vendors is the lost opportunities spent on wasted resources or “dusty

evaluation boards”. Designing, building, testing and shipping (often hand delivered) evaluation

boards is expensive and resources are valuable.

The Power Alliance, along with many semiconductor manufacturers are good examples of where

the industry has taken proactive steps to advance both the interests of engineers and suppliers.

An example of LoadSlammers being used today can be seen on this ASIC evaluation board

(http://www.powerstamp.org/psa-news/power-stamp-alliance-announces-asic-reference-designboard/).

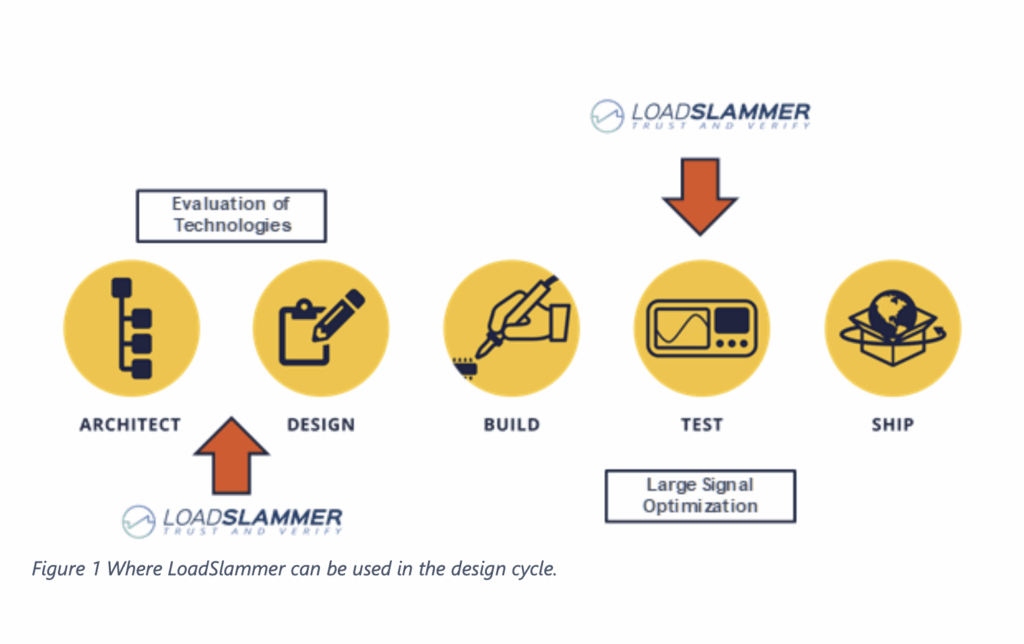

By using LoadSlammer technology, fast and thorough evaluations of regulator solutions can be

assessed.

The LoadSlammer family of products offers fast AC and DC measurements to be taken. When

measured in conjunction with large signal AC stimuli, Also Known As “Transient Load Testing”, a

sophisticated understanding of behavior of a vendor solution can be established before

implementing it into a system. Because LoadSlammer is vendor agnostic and mobile, fair

comparisons can be made against various solutions quickly and accurately.

After choosing and implementing a solution, engineers can then close the loop (pun intended)

on the design cycle by optimizing the finished solution. PID / compensation variables can be

tuned for the final product. Using the LoadSlammer API allows third party GUIs to test and

optimize with minimal interaction from the engineer.

Roger Beeston has spent his career, designing and selling, electronic systems, with a focus on

power supplies for advanced silicon products. Having been a design engineer for many years,

he is very familiar with the difficulty of implementing new technology under budget and on

time. He and his team developed the LoadSlammer with the intent of bridging the gap between

engineers and suppliers by providing consistent test information between different vendors’

solutions.